EN

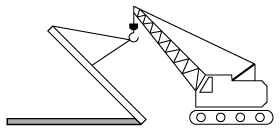

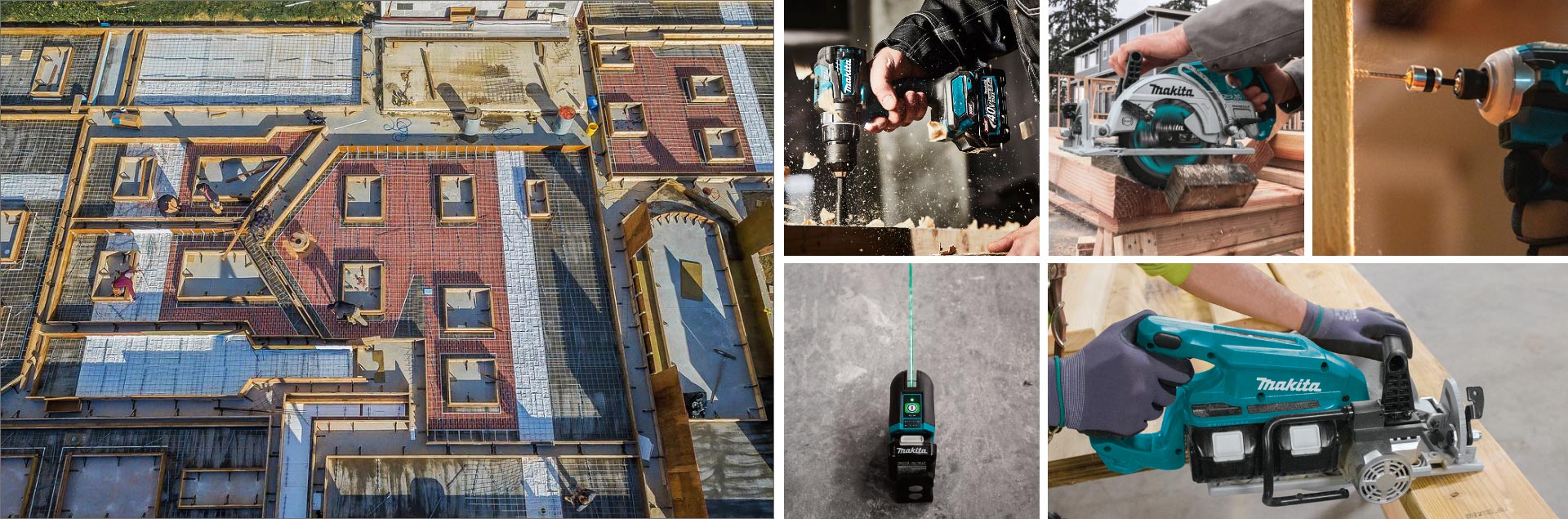

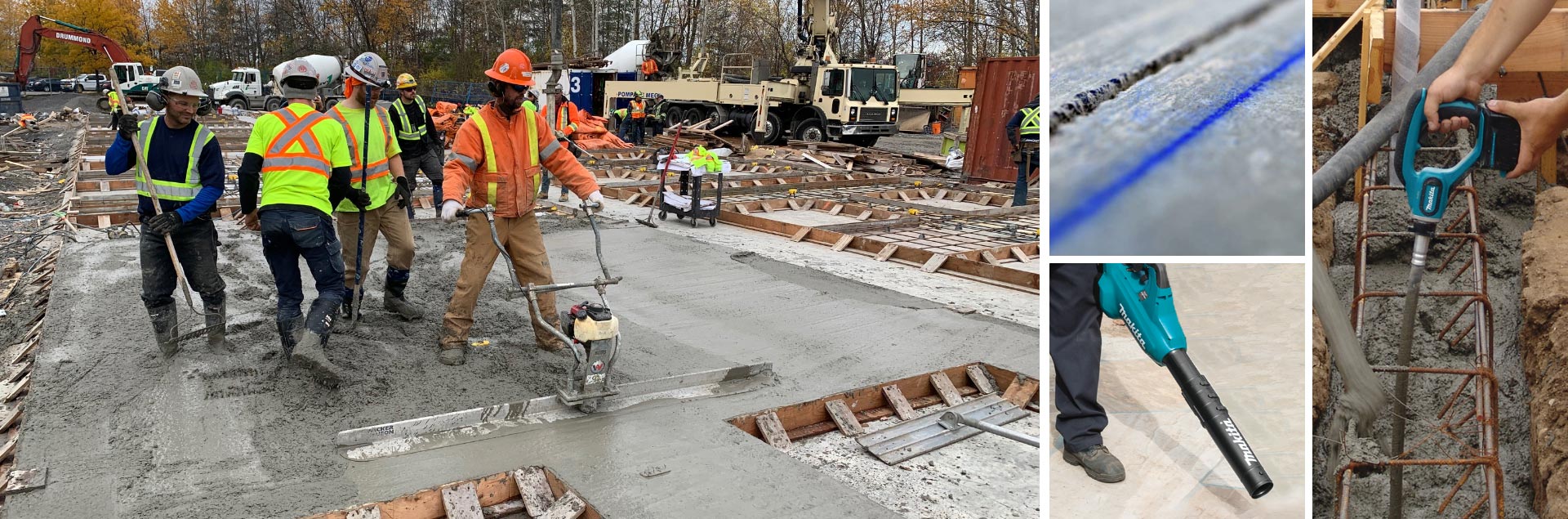

UNPLUG YOUR TILT-UP JOB SITE

Learn how Makita® cordless solutions can eliminate the hassle and expense of power cords from each phase of tilt-up construction.

ALIGNMENT &MEASUREMENT

Once the casting surface, also known as floor slab or pad, has cured, tilt-up panels can be created. Panels are measured and outlined in preparation for the formwork.

CUTTING

Dimensional lumber is often used to outline the edges and features of panels. Forms for the panels are laid out on the slab along the chalk lines.

FASTENING

Holes are drilled into the formwork, then nails or glue are used to keep the formwork in place.

INSTALLINGEMBEDDED ITEMS

Caulking is used to secure rustication, inserts, or embeds, such as structural supports and lifting hardware, to the panels.

CLEAN-UP

Prepare the surface by removing debris.

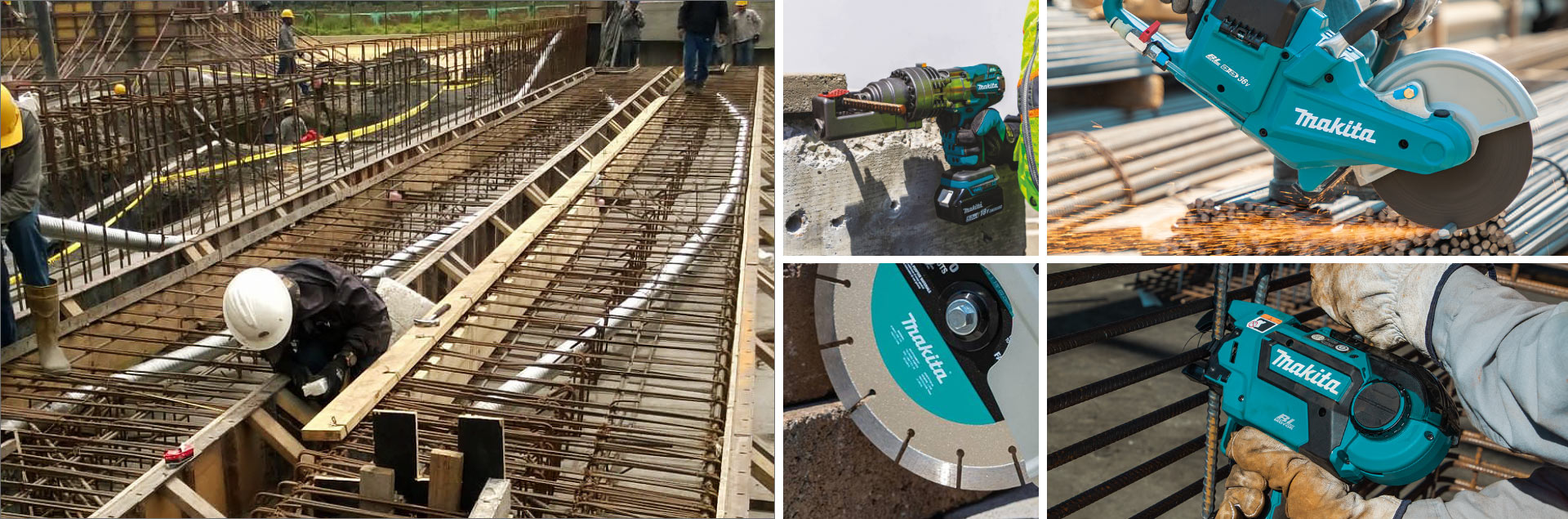

REBAR CUTTING

Rebar is used to strengthen the walls and cut to size.

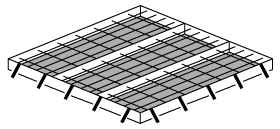

REBAR TYING

The rebar is laid down inside the form in a grid and secured together with wire.

-

XCS01T1

XCS01T1

- 18V LXT® Rebar Cutter Kit

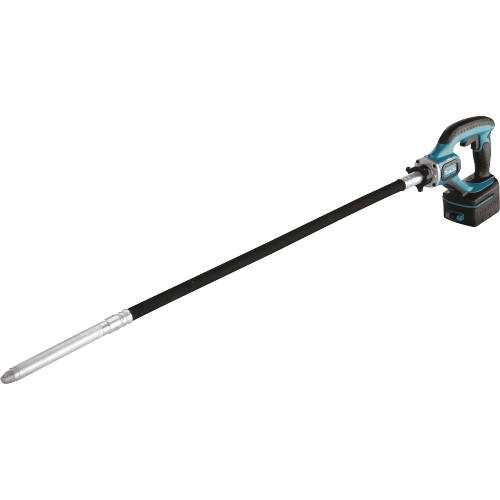

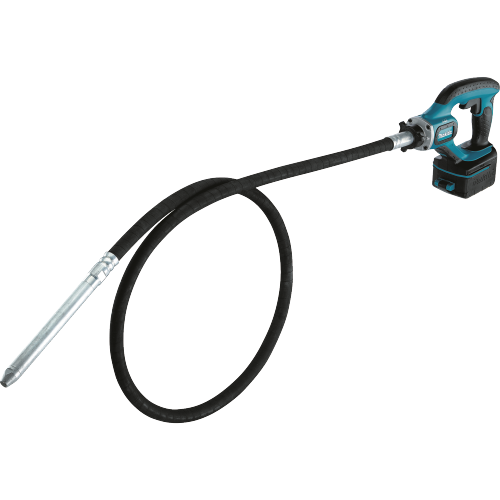

CONCRETECONSOLIDATION

Concrete vibrators are used to level concrete and remove entrapped air. This process helps ensure consolidation under and around embedded items.

WATER AND DUSTREMOVAL

Remove any excess water or debris from panel surfaces and edges.

DRILLING FORANCHOR

Rotary hammer is used to drill a hole for the anchor that will secure the brace.

ANCHORFASTENING

Impact Wrench is used to fasten the panel brace to the floor.

CONTROL &EXPANSIONJOINT CUTTING

Expansion joints are made to allow for the dynamic movement of the concrete that occurs due to ambient temperature variances and/or movement of the soil from seismic activity.

SLURRYCLEAN-UP

Vacuums and dust extractors can be used to remove slurry created during polishing, cutting, or grinding.

REMOVINGIMPERFECTIONSAND OVERPOURS

During the pouring process, concrete may cure in an imperfect manner if a form dislodges. Those imperfections are then removed first with demolition or rotary hammers.

CAULKING JOINTS& FILLING CRACKS

Joints and cracks should be filled before casting the panels.

CONCRETESURFACING

After removing imperfections, the panel is smoothed with angle grinders or concrete planers.

CLEAN-UP

Prepare the surface by removing debris.

-

GA5010Z

GA5010Z

- 5" Angle Grinder

-

PC5001C

PC5001C

- 5" Concrete Planer

YES – I WANT A DEMONSTRATION!

Please have a Makita representative contact me so I can test the best.

Makita Global

Makita Global